lorem

- Cylinders, Inc

- Blog

Can Hydraulic Cylinders Be Repaired? Knowing When It's Worth Repairing Instead of Replacing

Can Hydraulic Cylinders Be Repaired? Knowing When It's Worth Repairing Instead of Replacing

When facing a hydraulic cylinder issue, one of the critical decisions you'll need to make is whether to repair or replace the cylinder. Understanding the factors that determine when it's worth repairing a hydraulic cylinder rather than replacing it can help you save time, money, and resources.

In this blog post, our experts at Cylinders, Inc. make it easy to explore these factors. We provide insights and guidance to help you make an informed decision. Trust our professional team to provide expert hydraulic cylinder repair services. Let's dive into the world of hydraulic cylinder repair and find the best solution for your needs.

How to Tell If Your Hydraulic Cylinder Needs Repair

There are a few hydraulic cylinder failure symptoms that you should keep an eye out for. Knowing these warning signs can prevent everyday problems from quickly becoming catastrophic failures. The following are six signs that something is amiss with your hydraulic cylinders.

Loud Banging Noises

Loud banging or knocking noises coming from hydraulic cylinders are most likely caused by either excessive wear, aeration, or cavitation. Aeration occurs when air gets into the pump’s inlet and the intake lines become porous, letting more air in. This air then gets caught in the hydraulic system, creating air bubbles.

Air in a hydraulic cylinder results in a banging noise as the bubbles undergo decompression and compression while in circulation. Be sure to check intake lines regularly, and replace them if they become porous.

The other cause of loud knocking noises is cavitation. Cavitation is related to aeration, it occurs when there is not enough fluid reaching any part of a hydraulic circuit. This causes the pressure to drop so low that all of the fluid is essentially vaporized. As the pressure increases again, the cavity will implode on itself, making those loud noises and causing severe damage.

Both cavitation and aeration could result in damage to internal components of the system through overheating, breakdown of the seals, and loss of lubrication.

Hydraulic Cylinder Starts “Juddering”

A hydraulic cylinder lacking smooth and consistent movements is another sign of an underlying issue. “Juddering” is when the cylinder becomes jerky or stilted as the cylinder extends.

Juddering is often caused by physical damage from increased friction, worn-down seals, poor lubrication, or worse, the bending of the rod. An increase in the heat of the cylinder and energy required, as well as slow operation, may also occur and indicate that there's an issue with the hydraulic cylinder.

Power Bill Goes Up

Has your power bill been increasing? When there's an issue with your hydraulic cylinders, you might notice the problem when you check your power bill or fuel usage and see a number that's higher than usual. When there's internal or external leakage and increased friction, the system needs more energy to function.

In other words, the hydraulic pumps need to work harder by delivering more fluid to overcome the leakage.

Slowing Down of the Actuator

Another warning sign of issues with your hydraulic cylinder is the cylinder slowing down and losing power. The loss of power can generally be blamed on increased friction or internal leakage. If there's internal leakage, the cylinder will need more time to build up the necessary pressure, slowing down the whole process.

To overcome this inefficiency, many operators will turn up the power. But this only masks the real problem. The cylinder’s performance will continue to decline until it's no longer functional because the underlying damage hasn't been addressed and repaired.

Overheated Cylinder

There are general guidelines and limits for the temperature of a hydraulic cylinder prescribed by the manufacturer. When the cylinder begins to heat past those limits, that's a sign of a bigger problem with the system’s capacity to regulate the heat load. Overheating can be caused by friction between its moving parts, contaminated fluid, low fluid levels, and poor oil filtration.

Uneven Piston Rod Wear

A cylinder runs linearly and should therefore wear linearly, as well. If one side of a rod is showing more wear than the other, this is a good indication something in the cylinder isn't functioning how it should. This could mean there is a misalignment, a bent rod, excessive lateral loading, or another form of internal damage. Make sure to regularly check your pistons for any signs of uneven wear.

A Review of Hydraulic Cylinder Failure

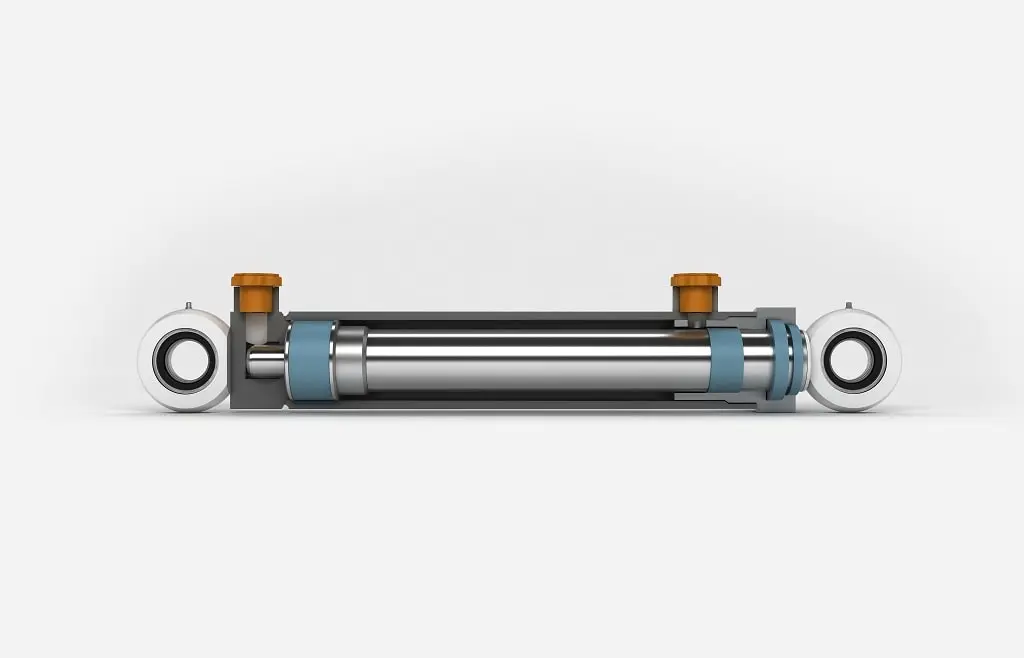

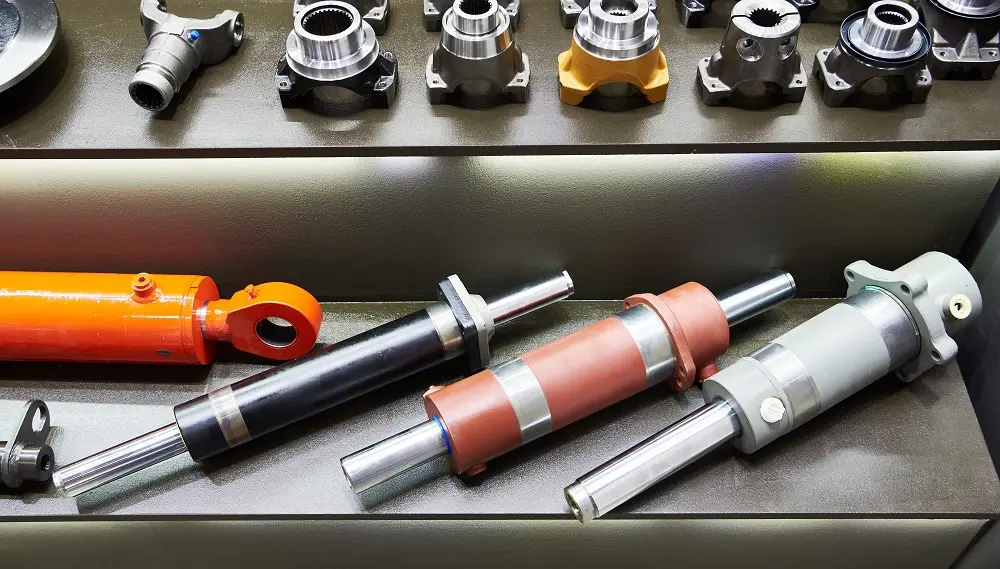

A hydraulic cylinder is made up of many small and large parts. The most common components that fail are the barrel which contains many of the other parts, the cylinder cap, the cylinder head, the piston rod, the piston that transfers motion to the piston rod, and the many seals and bearings of the cylinder.

If any part is damaged, it can reduce the efficiency and performance of the cylinder as a whole, or at worst, render it completely useless. There are plenty of hydraulic cylinder failure symptoms, so make sure to inspect the hydraulic cylinder for the telltale signs of hydraulic cylinder malfunction. We've outlined some more specific details for you below.

Contaminated Hydraulic Fluid

Hydraulic cylinder failure can occur for many reasons and come in different forms. Contaminated hydraulic fluid or hydraulic oil is a common issue that can accelerate wear and damage critical seals. Often the failure will appear to be sudden when in reality it has been building for some time.

Priston Rods

Piston rods can be bent, barrels and the cylinder rod can be dented, all resulting in catastrophic issues, and corrosive chemicals and natural elements can damage piston seals and metal. Eye bearing and piston rod bearings are known to wear out and lead to hydraulic cylinder failure.

Tie-Rods

However, there are limits to repairability. NFPA cylinders commonly use square caps that are spanned and attached to a barrel using tie rods. These tie-rods are generally threaded into the cap or head, typically on one side, while the other side is secured with a high-strength nut. The process of cylinder repair is expedited by removing the nuts and tie rods as the whole assembly can usually be disassembled easily.

Head Damage

Hydraulic cylinder failure can occur due to various factors, and one common area that can experience issues is the cylinder head. From seal failures to cracking or excessive wear, problems with the head can result in loss of hydraulic pressure and compromised performance. You'll need to regularly inspect, get proper maintenance, and make repairs promptly to prevent and address potential failures in the hydraulic cylinder head.

Should I Repair or Replace a Hydraulic Cylinder?

The decision to repair or replace a hydraulic cylinder has many considerations besides cost that should be considered. If you were to make a pro and con list, the cost would only be one of the many factors that are listed to help you make the best decision.

Cylinder's Life Expectancy

No system lasts forever, and wear cannot be avoided. If the hydraulic cylinder has passed its “working life,” and is beyond economical repair it might make more sense to replace rather than repair it.

What to choose: Replace

Availability

Depending on the age or brand of the cylinder, that type of cylinder may no longer be manufactured. It can also be difficult to find a replacement for a non-standard cylinder. COVID-19 has made it difficult to find certain products, including cylinders. If you can't easily find a replacement, hydraulic cylinder repairs may be the better choice.

What to choose: Repair

Number of Damaged Parts of Hydraulic Cylinder

The number and type of components damaged within the cylinder also affect how cost-efficient the overall cost of repairs and replacement will be. Often, when one component is malfunctioning, others will pay the price for its poor performance. Determining the number of components that are damaged can help you determine whether it's better to repair or simply replace them.

What to choose: Tie

Extent of Damage

Assess the extent of damage to the hydraulic cylinder. If the damage is minor and can be repaired, it could be more cost-effective to opt for repairs. However, extensive damage or structural issues may require a complete replacement.

What to choose: Tie

Compatibility Issues

Sometimes, older hydraulic cylinders may be discontinued or have limited availability. Repairing an existing cylinder ensures that you can continue using the original equipment without any compatibility issues.

What to choose: Repair

The Cause of Failure

The root cause of failure is an essential part of determining the best approach. If you were to replace a failed cylinder without knowing why it failed, it'll most likely happen again with the new one, as the same, unadjusted practices will be employed. If only one small part fails, resulting in the weakening of the entire hydraulic system, then it can be easily repaired, at a lower cost to you.

What to choose: Repair

Benefits of Hydraulic Cylinder Repair

There are substantial benefits to repairing a hydraulic cylinder over replacing it. In many cases, only one specific component is damaged or in need of repair, not the entire cylinder.

Assuming the failure was noticed sooner rather than later and other parts are still in good condition, it's only necessary to replace the failed part. This will make the overall hydraulic cylinder repair more cost-effective, saving your business money.

Availability

There's always a high availability of companies with the equipment, experience, and facilities to effectively repair a hydraulic cylinder, no matter its make or model.

Quality of Repair

Do some research and choose the most reputable repairer with optimal equipment and processes so you can ensure the highest quality repair.

More Choice

This affords you the ability to choose your preferred repairer based on pricing, quality, experience, or any other factor you choose to prioritize.

Costs of Repair and Replacement of Hydraulic Cylinders

In some cases, a hydraulic cylinder can become so damaged that there's no choice but to replace it. Most of the time, however, that isn't the case. A cylinder can be repaired by skilled experts to resemble or closely resemble its original condition. The upfront price to repair the hydraulic cylinder is less than the average cost of getting a new cylinder, but there are other costs to consider, as well.

Time that Repairing Hydraulic Cylinder Will Take

When a cylinder fails, it takes time to get it repaired or replaced. From shipment to manufacturing to installation, that downtime comes at the expense of your business. Try to calculate how much it'll cost to repair and replace this part, factoring in the number of non-operational days that will accumulate.

Energy-Efficiency Costs

There might also be efficiency costs to consider when making this decision. Natural wear or accelerated wear from failing components will lower the overall efficiency of the hydraulic system. To compensate for the energy losses, the worn-out hydraulic system uses more power.

Regularity of Repair

The frequency of replacement should also be considered. If you find yourself replacing your cylinders often, it could be a sign that there's an issue with your cylinder use. It might be more cost-effective to have them repaired instead of replacement of an entire cylinder as it'll be more cost-efficient and the professional you hire will have insight into what's wrong with your cylinder.

How to Choose Your Hydraulic Cylinder Repair Services Provider

Choosing the right hydraulic cylinder repair service provider is crucial, whether it's for bent rods, damaged cylinders, or complete replacement services.

To make sure you receive high-quality service that meets your needs, here are some factors to consider:

- Expertise and experience: The provider should have a deep understanding of different types of hydraulic cylinders, common causes of failure, and effective repair processes and techniques. They should be familiar with the brands and models in your operation and have a solid track record of successful repairs;

- The reputation & reviews: Are they known for their reliability, quality of work, and customer service? Checking online reviews and asking for referrals can give you a sense of what to expect;

- Facilities and equipment: Advanced technology and a well-equipped workshop can often mean more precise and efficient repairs;

- Customer service: A good provider will take the time to explain the problem, the proposed solution, and the costs involved. They should also be responsive and keep you updated on progress;

- Cost-effectiveness: While it's important not to compromise on quality, make sure that the provider's pricing is transparent and competitive.

Get Your Hydraulic Cylinder Repaired Today!

At Cylinders, Inc., we're experts in hydraulic cylinder repairs and we're committed to bringing you superior service using only the highest quality materials. Rely on our team to be efficient, collaborative, and cost-effective, so you can get back to work as soon as possible. If you have issues with your cylinders, our hydraulic cylinder experts are at your service. Call today and schedule your repair, rebuild, or pressure testing today!

Recommended posts

Got a Cylinder to Fix?

REQUEST A REPAIR%20(2)%20(1).webp)

Quality Cylinder Repairs Save You Big

Don't replace - repair! Our experts can fix any hydraulic cylinder damage. Request a quote to restore yours today.

%20(1).webp)

Contact

Request Your Cylinder Repair Today

Have a question about our pneumatic cylinder repairs? Contact Cylinders, Inc. to find out more about how our experts can help, or schedule your repair service today!